In today’s fast-paced manufacturing environment, efficiency and productivity are key to staying competitive. A recent study revealed that implementing automated packaging solutions can enhance production efficiency by up to 50%, highlighting the substantial impact of such technologies. [1] One area where significant improvements can be made is in the packaging process, particularly through the automation of flow wrappers. This blog post will delve into the advantages of automated packaging services, focusing on custom automation services in the UK, and how they can transform your manufacturing process.

Introduction to Flow Wrapper Automation

Understanding Flow Wrapping

Flow wrapping is a packaging process used to wrap products using a clear or printed polypropylene film. This method is ideal for a wide range of products, from food items to consumer goods. Automating this process can lead to significant improvements in speed, efficiency, and cost-effectiveness.

The Shift to Automation

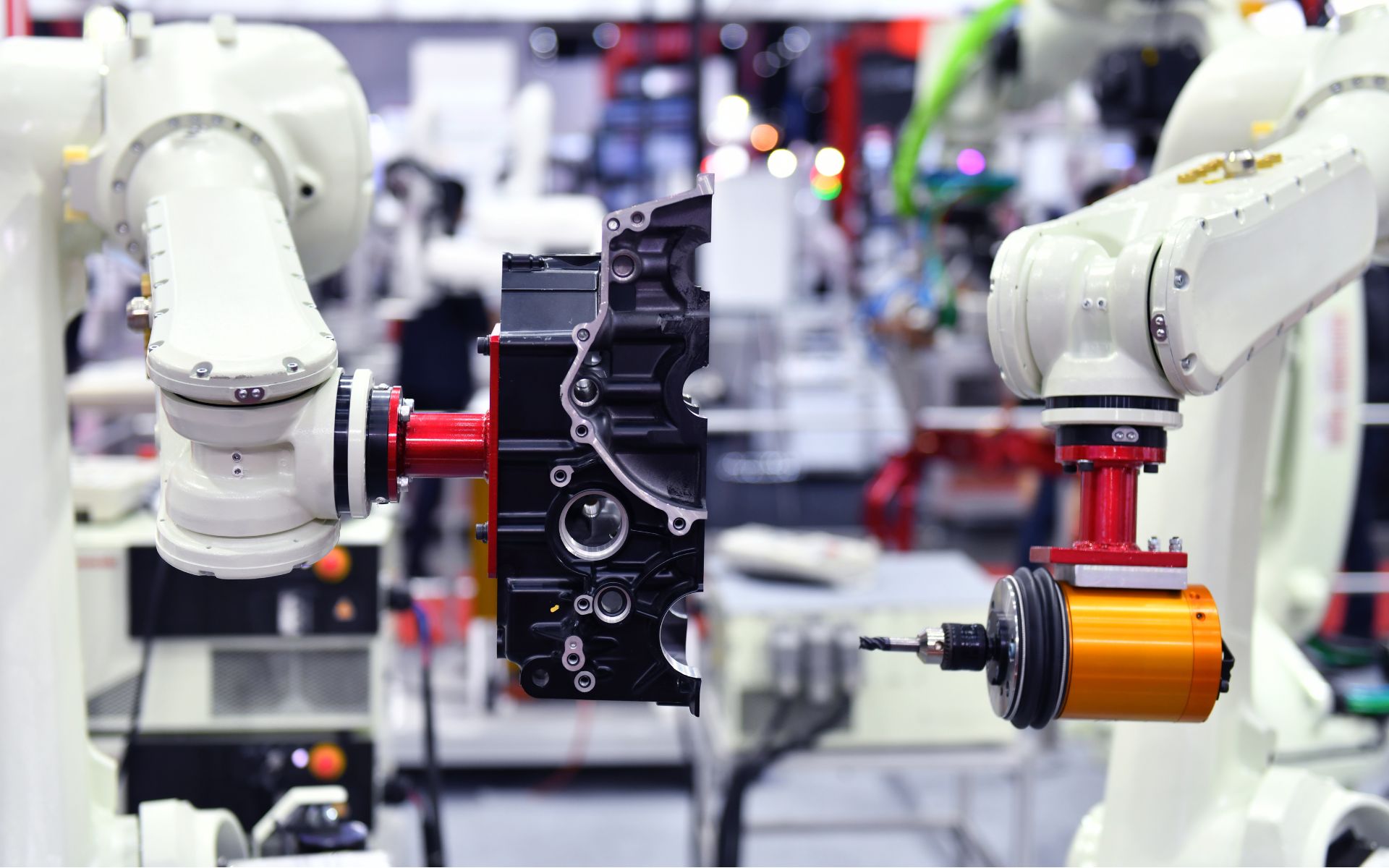

The shift towards automating the flow wrapping process is driven by the need to meet higher production demands and maintain consistent quality. Automated flow wrappers offer precision and speed that manual packaging processes cannot match.

The Benefits of Automated Packaging Services

Increased Productivity and Efficiency

Automated flow wrappers operate at a much faster rate than manual packaging, significantly increasing production output. This speed doesn’t come at the cost of quality; these machines are designed to ensure each product is wrapped consistently and securely.

Consistency and Quality Assurance

Automating the flow wrapping process guarantees a consistent level of quality that is difficult to achieve manually. Uniform packaging not only improves the aesthetic appeal of the product but also enhances product protection during transport and storage.

Cost Reduction and Scalability

With the reduced need for manual labor, companies can cut down on labor costs. Furthermore, automated packaging machines are scalable; they can be adjusted to accommodate different product sizes and packaging styles, providing flexibility as product lines expand or change.

Custom Automation Services in the UK

Tailoring Solutions to Specific Needs

The UK’s manufacturing sector is diverse, requiring packaging solutions that cater to specific needs. Custom automation services allow for the development of bespoke solutions, ensuring that the automated flow-wrapping process aligns perfectly with the product and production line requirements.

Integration with Existing Production Lines

A major advantage of custom automation services is their ability to integrate seamlessly with existing production lines. This integration ensures that the transition to automated flow wrapping is smooth and does not disrupt the existing manufacturing process.

The Role of Innovation

UK-based custom automation service providers are at the forefront of packaging innovation. They continually develop and implement new technologies to improve the efficiency and capability of automated flow-wrapping machines.

The Environmental Aspect

Reducing Waste

Automated packaging services contribute to environmental sustainability by reducing waste. Precision in packaging means less material is used, and consistency ensures minimal errors, leading to less product wastage.

Energy Efficiency

Modern automated flow wrappers are designed to be energy efficient, which is not only good for the environment but also reduces operational costs.

Case Studies: Success Stories in Automation

Food Industry

In the food industry, automating flow wrapping has streamlined the packaging of perishable goods, ensuring products reach consumers faster and in optimal condition.

Consumer Goods

For consumer goods, automated flow wrapping has allowed quicker turnaround times, efficiently meeting the high demand in retail sectors.

Overcoming Challenges in Automation

Initial Investment

While the initial investment in automated packaging machinery can be high, the long-term ROI justifies the expense. Increased productivity, reduced labor costs, and improved product quality all contribute to a quick return on investment.

Training and Maintenance

Implementing automated systems requires an investment in training and maintenance. Ensuring that staff are well-trained to operate and maintain these machines is crucial for the long-term success of the automation process.

The Future of Automated Packaging

Advancements in Technology

The future of automated packaging is bright, with ongoing advancements in technology making these systems more efficient, versatile, and user-friendly.

Customization and Flexibility

As market demands continue to evolve, the ability to customize and adapt packaging machinery will be crucial. Flexibility in dealing with various product types and sizes will be a key factor in the future of automated flow wrapping.

Partnering with WorldOneAutomation for Success

In conclusion, automating the flow wrapping process in your manufacturing operation can lead to substantial gains in productivity, efficiency, and cost savings. For those seeking to embrace these benefits, partnering with a provider like WorldOneAutomation is an excellent choice. They offer a range of automated packaging services and custom automation solutions tailored to meet the unique needs of businesses in the UK and beyond.

Whether you’re looking to upgrade your current packaging process or implement a new automated system, WorldOneAutomation has the expertise and technology to help you achieve your production goals.