In manufacturing and quality control, the integration of advanced technologies like PLC and Machine Vision Systems has revolutionized the industry. Machine Vision Systems alone have reduced defects by 20% and increased production throughput by 15%, according to recent industry data. [1] This post explores their advantages in quality control and their synergy with machines from World One Automation.

Introduction to Machine Vision Systems

Defining Machine Vision Systems

Machine Vision Systems refer to technology that uses imaging-based inspection for various applications in industry, especially in manufacturing and quality control. These systems combine software and hardware to guide manufacturing and quality control processes, using cameras and image processing to inspect and analyze products.

The Role of PLC in Enhancing Machine Vision

PLCs play a crucial role in automating manufacturing processes, and when integrated with Machine Vision Systems, they create a more robust and efficient quality control system. PLCs can be programmed to react based on the input from Machine Vision Systems, automating decision-making processes and reducing the need for human intervention.

Advantages of Machine Vision Systems in Quality Control

Enhanced Accuracy and Precision

One of the primary benefits of Machine Vision Systems in quality control is their ability to inspect products with a level of accuracy and precision that far exceeds human capabilities. These systems can detect minute defects, ensuring that only products that meet stringent quality standards reach the market.

Increased Production Efficiency

Machine Vision Systems significantly speed up the quality control process. Unlike manual inspections, which can be time-consuming and prone to errors, these systems can inspect products rapidly and consistently, thus increasing overall production efficiency.

Cost Savings and ROI

Implementing Machine Vision Systems can lead to substantial cost savings in the long run. By reducing the rate of defects and returns, these systems enhance the overall quality of the product, thereby improving customer satisfaction and brand reputation. Additionally, the reduction in manual labor for quality control can be a significant cost-saving factor.

Consistency in Quality Control

Machine Vision Systems provide consistent and repeatable inspection results, which is critical in maintaining product quality. This consistency is essential for manufacturers to adhere to industry standards and regulatory compliance.

Integration of Machine Vision Systems with Individual Machines

Customization and Flexibility

Machine Vision Systems can be customized and integrated with individual machines in a production line. This flexibility allows for tailored quality control processes suited to specific products or manufacturing environments.

Real-Time Feedback and Adjustments

These systems provide real-time feedback, enabling immediate adjustments to be made in the manufacturing process. This immediate response is crucial in preventing the proliferation of defects and ensuring continuous production without significant downtime.

Data Collection and Analysis

Machine Vision Systems not only inspect and identify defects but also collect valuable data. This data can be analyzed to identify trends, improve manufacturing processes, and make informed decisions about quality control protocols.

Case Studies and Applications

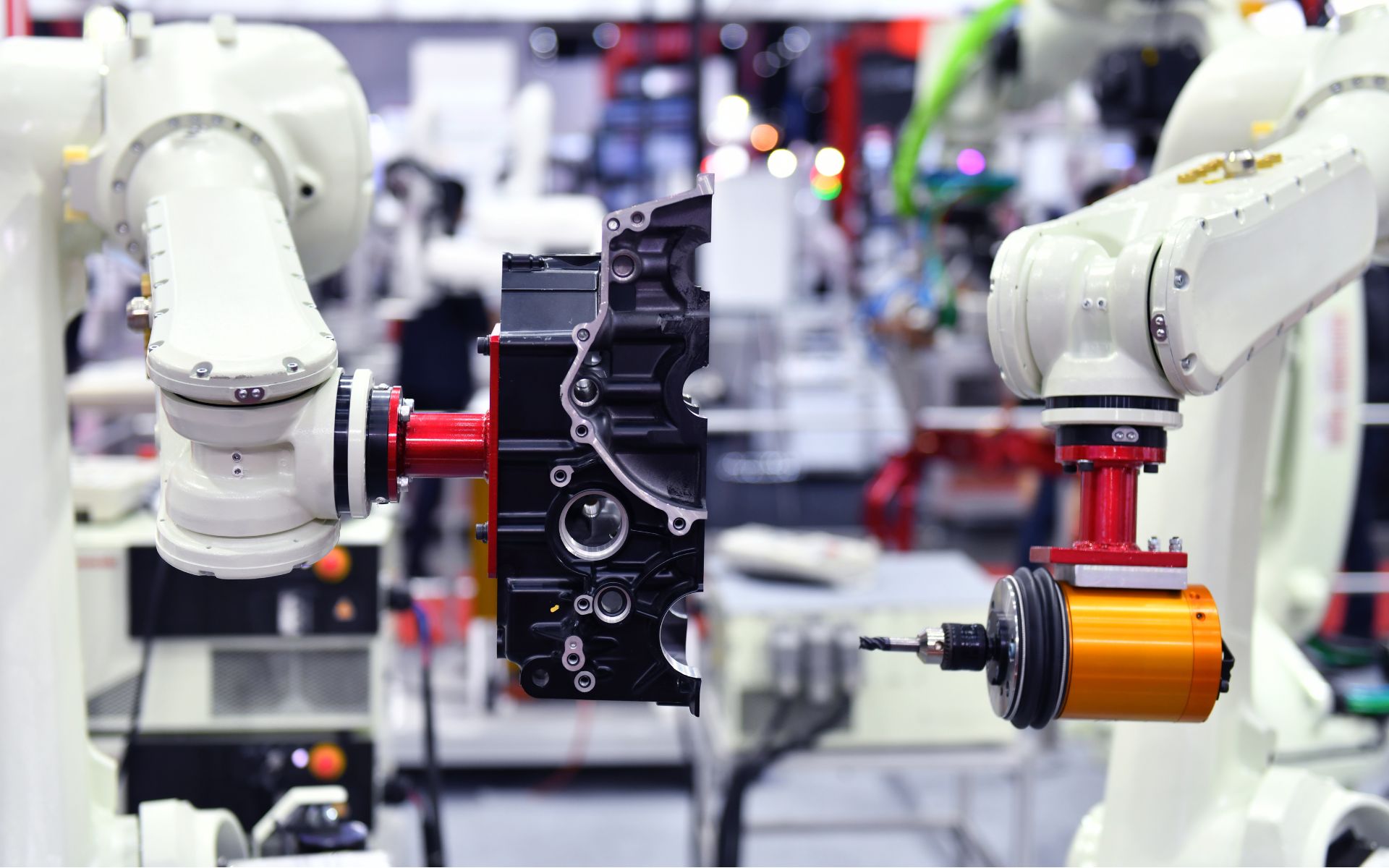

Automotive Industry

In the automotive industry, Machine Vision Systems are used to inspect individual components and assemblies, ensuring that each part meets the required specifications and tolerances.

Electronics Manufacturing

For electronics manufacturers, these systems are indispensable in inspecting circuit boards and components for defects that are not visible to the naked eye.

Food and Beverage Industry

In the food and beverage sector, Machine Vision Systems are used to ensure packaging integrity, label accuracy, and product quality.

The Future of Machine Vision in Quality Control

Advancements in AI and Machine Learning

The integration of AI and machine learning algorithms in Machine Vision Systems is set to enhance their capabilities further, enabling more sophisticated analysis and decision-making processes.

IoT Integration

The integration of IoT (Internet of Things) with Machine Vision Systems will enable better connectivity and data exchange across manufacturing processes, paving the way for more efficient and intelligent production lines.

Conclusion:

The adoption of Machine Vision Systems in quality control is no longer a luxury but a necessity for manufacturers aiming to maintain high standards in product quality. These systems, along with PLC integration, play a vital role in ensuring efficiency, consistency, and precision in manufacturing processes.

For manufacturers seeking to implement these advanced technologies, partnering with a seasoned and skilled provider is crucial. World One Automation offers comprehensive solutions in PLC and Machine Vision Systems, ensuring that your manufacturing processes stay ahead of the curve in quality control and efficiency.