Machine vision systems enable machines to capture and process images and extract information from their environment. Machine vision systems can perform tasks such as inspection, identification, measurement, guidance, and control, using cameras, sensors, software, and artificial intelligence. Machine vision systems have been widely used in various industries, especially in manufacturing, to improve quality, efficiency, productivity, and safety.

In this article, we will explore how machine vision systems improve manufacturing, and how we can help you implement them in your factory.

Machine vision systems can improve manufacturing in many ways, such as:

• Quality assurance:

Using high-resolution cameras and image processing algorithms, machine vision systems can inspect products and components for defects, errors, or deviations from specifications. Machine vision systems can detect flaws that are too small, too fast, or too complex for human eyes, and reject faulty products or alert operators for corrective actions. Machine vision systems can also verify the presence, position, orientation, and size of parts, labels, barcodes, or markings, and ensure compliance with standards and regulations. Machine vision systems can improve the quality and consistency of products, reduce waste and rework, and enhance customer satisfaction and loyalty.

• Process optimization:

Machine vision systems can monitor and control the manufacturing process, using real-time data and feedback from sensors and cameras. Machine vision systems can adjust the parameters, settings, or speed of machines, equipment, or robots, based on the input or output conditions, and optimize the performance and efficiency of the process. It can also collect and analyze data from the process, and provide insights and recommendations for improvement, such as reducing cycle time, energy consumption, or downtime. Machine vision systems can improve the manufacturing process’s productivity and profitability, enabling continuous improvement and innovation.

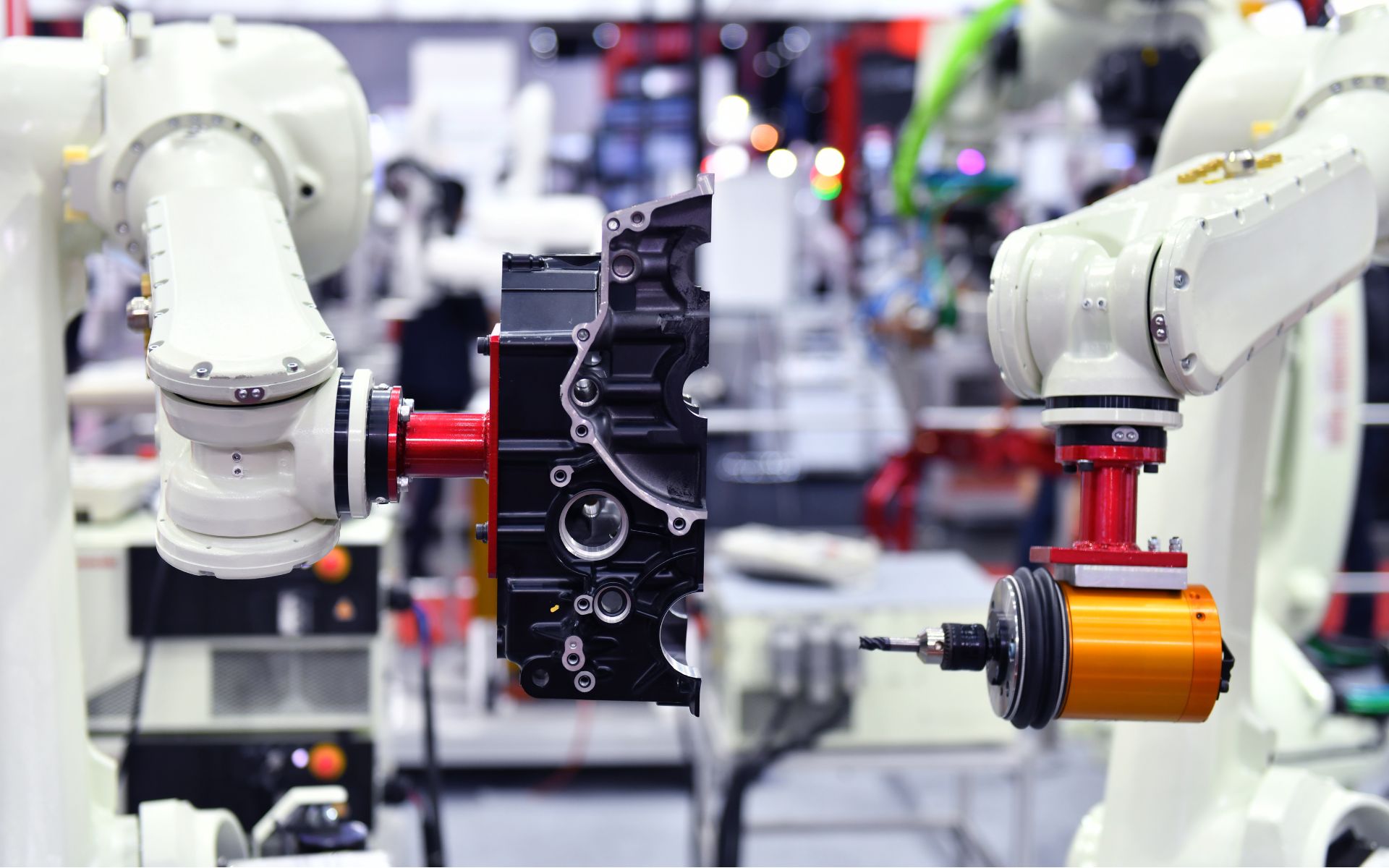

• Automation and integration:

Machine vision systems can automate and integrate various tasks and functions in manufacturing, using robotics, artificial intelligence, and the Internet of Things. Machine vision systems can guide and coordinate the movements and actions of robots, such as picking, placing, assembling, or welding, using cameras and sensors. It can also communicate and interact with other machines, equipment, or systems, using wireless networks and protocols, and synchronize the operations and workflows of the manufacturing process. Machine vision systems can improve the flexibility and scalability of the manufacturing process, and reduce the reliance on human labor and intervention.

Choose World One Automation

We are a leading provider of machine vision systems and solutions for the manufacturing industry. World One Automation can help you design, install, commission, and maintain your machine vision systems, using the latest technologies and best practices. World One Automation can help you:

• Design:

World One Automation can help you design your machine vision systems, based on your specific needs and goals. We can help you select the right cameras, sensors, software, and hardware for your machine vision applications, and integrate them with your existing machines, equipment, or systems. We can also help you develop and train your machine vision algorithms, using machine learning and artificial intelligence, and customize them for your products, components, or processes.

• Install:

World One Automation can help you install your machine vision systems, using professional and experienced engineers and technicians. World One Automation can help you mount, position, align, and connect your cameras, sensors, and other components of your machine vision systems, and ensure they are properly calibrated and configured. We can also help you test and verify your machine vision systems, and ensure they function correctly and accurately.

• Commission:

World One Automation can help you commission your machine vision systems, using rigorous and systematic procedures and methods. We can help you start up, operate, and optimize your machine vision systems, and ensure they are ready for production. We can also help you validate and document your machine vision systems, and ensure they meet the requirements and specifications of your project.

• Maintain:

We can help you maintain your machine vision systems, using preventive and corrective maintenance services and support. We can help you monitor, troubleshoot, and repair your machine vision systems, and ensure they are running smoothly and reliably. We can also help you upgrade, update, or modify your machine vision systems, and ensure they are compatible and compliant with the latest technologies and standards.

Contact Us Now

If you are interested in improving your manufacturing process with machine vision systems, contact us today. We can help you achieve your quality, efficiency, productivity, and safety goals, and give you a competitive edge in the market. World One Automation is your trusted partner for machine vision systems and solutions. Contact us now.